When your engine fails, the stress hits fast. Your car won’t move, repair bills start piling up, and suddenly you’re forced to make a decision you probably never planned for. Most drivers end up stuck between two popular options: going with a replacement motor pulled from another vehicle or choosing a rebuilt unit that’s been torn down and reassembled.

At first glance, both sound reasonable. But when you dig deeper, the differences between them are bigger than most buyers realize. Cost, reliability, downtime, and long-term value all play a role—and that’s where many people get tripped up. Let’s break this down in plain language so you can figure out which option actually fits your budget and your situation best.

Understanding the Two Options Without the Jargon

Before comparing costs, it helps to understand what you’re really paying for.

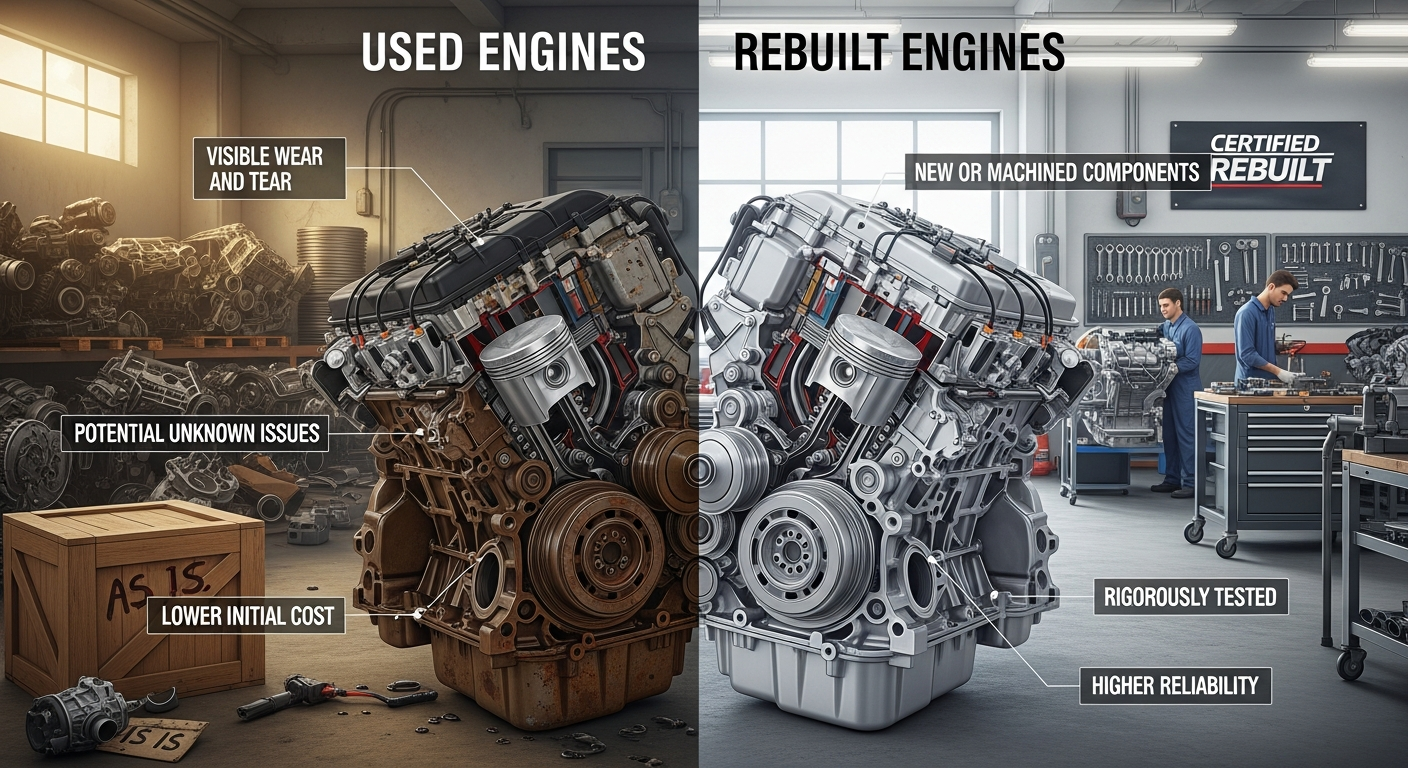

A replacement motor is taken from another vehicle, usually one that was retired due to an accident or non-mechanical issue. These motors are inspected, tested, and sold as complete units.

A rebuilt engine, on the other hand, is disassembled, cleaned, and reassembled using a mix of old and new components. Worn parts are replaced, and tolerances are brought back within factory specifications—at least in theory.

Both approaches can work. The key is knowing where each one makes sense.

Upfront Cost: The First Budget Reality Check

Let’s talk money right away, because that’s where most decisions start.

Rebuilt engines are usually more expensive upfront. The labor involved in tearing down, machining, and reassembling an engine adds significant cost. Depending on the vehicle, this can push the price uncomfortably close to what the car itself is worth.

Replacement motors generally cost less because they don’t involve full disassembly and machining. That price gap is one of the main reasons used engines remain so popular among everyday drivers trying to stay within a realistic budget.

If your goal is minimizing immediate out-of-pocket expense, this difference alone can be a dealbreaker.

The Hidden Costs Most Buyers Miss

Upfront pricing doesn’t tell the full story. What matters just as much is what comes after installation.

Rebuilt engines can sometimes require longer installation times due to fitment adjustments or break-in procedures. That means more labor hours, more downtime, and more cost.

Replacement motors are typically installed as complete units, which often reduces labor time. Less time in the shop means lower installation bills and faster turnaround.

That difference doesn’t always show up on the quote—but it definitely shows up on the final invoice.

Reliability: Perception vs Reality

Many buyers assume rebuilt automatically means more reliable. That’s not always true.

A rebuilt engine is only as good as:

The quality of parts used

The precision of machining

The skill of the rebuilder

The consistency of quality control

Cut corners anywhere in that process, and reliability suffers.

Replacement motors, when properly sourced and tested, often come from vehicles that were running perfectly before being retired. Compression testing, mileage verification, and inspection play a huge role here.

This is why used engines sourced from reputable suppliers can be just as dependable as rebuilt ones in real-world driving.

Mileage vs Machining: Which Matters More?

This is a question most buyers never ask, but should.

A rebuilt engine may have zero miles since rebuild, but many internal components are still reused. Meanwhile, a replacement motor with verified low mileage may have experienced far less wear overall.

Mileage tells a story. It reflects real-world use, maintenance habits, and operating conditions. Machining resets tolerances, but it doesn’t always reset long-term durability if lower-quality parts are used.

Understanding this balance helps explain why replacement motors often perform better than buyers expect.

Warranty Isn’t Always What It Seems

Warranty terms can look impressive on paper, but the fine print matters.

Rebuilt engine warranties often include strict conditions, such as mandatory break-in documentation, frequent oil changes, and limited coverage for labor.

Replacement motor warranties tend to be more straightforward, especially when purchased from established suppliers. Turbo Auto Parts focuses on clear warranty terms that align with real-world usage, which is why many buyers feel more confident choosing that route.

A warranty only has value if it’s easy to understand and realistically usable.

Downtime Has a Cost Too

Time without a vehicle costs money, even if it doesn’t show up as a line item.

Longer rebuild lead times mean:

Missed work

Rental car expenses

Disrupted routines

Replacement motors are usually ready to ship faster, which shortens downtime significantly. For many drivers, that convenience alone tips the scale.

Installation and Supporting Components

No matter which option you choose, installation quality is critical. This is also where smart buyers create extra value.

During installation, technicians often replace:

Seals and gaskets

Belts and hoses

Fluids and filters

This creates a clean baseline for future maintenance.

In some cases, shops also evaluate Used transmissions during the process, especially when the drivetrain has similar mileage. Addressing issues while everything is accessible can reduce future labor costs and improve overall drivability.

Performance After Installation

Most drivers don’t want more power—they want normal, dependable performance.

A good replacement motor restores:

Smooth acceleration

Stable idle

Consistent fuel economy

Quiet operation

A rebuilt engine should do the same, but inconsistencies in rebuild quality can lead to variations in performance.

For everyday driving, the difference is often negligible when both options are done right. That’s why budget considerations end up carrying more weight for most buyers.

Long-Term Ownership Costs

Keeping a car long-term means thinking beyond the repair itself.

Replacing your vehicle introduces:

New insurance costs

Taxes and registration fees

Faster depreciation

Financing interest

Replacing the engine avoids all of that. For many owners, this makes used engines the more budget-friendly choice over the life of the vehicle, not just at the time of repair.

Environmental Considerations

There’s also a sustainability angle that rarely gets attention.

Rebuilding requires machining, new parts manufacturing, and energy-intensive processes. Reusing an existing motor avoids much of that environmental cost.

Choosing a replacement motor reduces waste and maximizes the use of already-produced resources—an added bonus for eco-conscious drivers.

Supplier Quality Changes Everything

The biggest variable in this entire comparison isn’t the engine type—it’s who you buy from.

Turbo Auto Parts stands out by focusing on compatibility checks, testing transparency, and customer support. That reduces risk and helps buyers feel confident they’re making the right choice.

A well-sourced replacement motor beats a poorly rebuilt one every time.

When Rebuilt Engines Make Sense

To be fair, rebuilt engines aren’t a bad choice in every situation.

They can make sense when:

Original engines have known design flaws

Long-term ownership is guaranteed

A trusted local rebuilder is available

In these cases, paying more upfront can offer peace of mind.

When Replacement Motors Win on Budget

For most drivers, especially those with older or paid-off vehicles, replacement motors offer the best balance of cost and reliability.

They’re ideal when:

Budget flexibility is limited

Quick turnaround is needed

The rest of the vehicle is in good shape

This is why used engines continue to dominate the replacement market.

Don’t Forget the Drivetrain as a Whole

An engine swap is also a chance to evaluate the rest of the drivetrain. In some cases, inspecting or replacing Used transmissions at the same time creates a smoother, more reliable driving experience without dramatically increasing cost.

This strategic approach maximizes labor efficiency and long-term value.

Final Thoughts

Choosing between a rebuilt engine and a replacement motor isn’t about which option sounds better—it’s about which one fits your real-world budget, timeline, and expectations.

For many drivers, replacement motors deliver dependable performance, faster turnaround, and lower overall costs. When sourced responsibly and installed correctly, used engines provide a practical, budget-friendly solution that keeps reliable vehicles on the road.

With support from trusted suppliers like Turbo Auto Parts, the decision becomes less stressful and far more predictable—exactly what most car owners need when facing a major repair.

Read Also: Engine for Sale Simplified: Tips for First-Time and Experienced Buyers

Write a comment ...